About Four-die forging devices

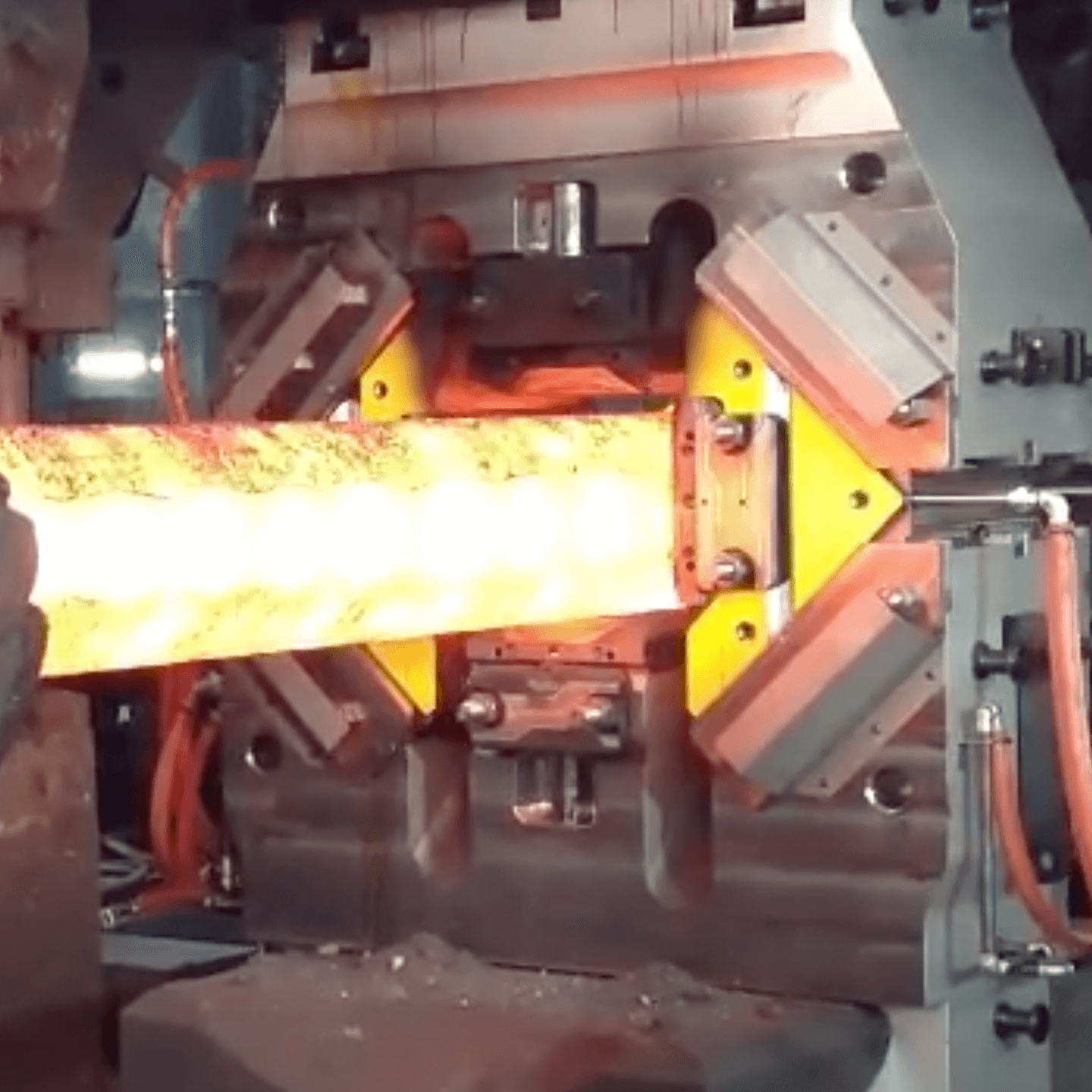

AMJ has concluded an exclusive sales agreement for four-die forging devices (FDFDs) with Dr. Viktor Lazorkin (Lazorkin Engineering, LLC) of the Ukraine. Four-die forging devices are used for the production of high-quality steel materials that require high-mechanical strength. They work by horizontally applying pressure to the material simultaneously from all four sides.

The FDFD was developed by Dr. Viktor Lazorkin of the Ukraine, a country that has traditionally had a thriving steel industry. It is now employed in a number of major steel producing countries, including Russia, Germany, Italy, and China. One of the most appealing features of the FDFD is that it is relatively easy to adopt, because it can be fitted to an existing hydraulic forging press.

The FDFDs we offer are designed and made to order in accordance with the specific facilities and manufacturing environment of each customer.

Higher raw material yield

Since pressing occurs simultaneously on all four sides, there is no horizontal extension of the metal, resulting in forgings of very high dimensional precision (approximately 2 to 2.5 times lower tolerance and 1.5 times lower tolerance interval). This increased precision increases the efficiency of finishing processes significantly. Studies have reported that an FDFD can save about 40 to 50 kg of metal per ton of forging production.

Simpler processes

Since an FDFD reduces the number of strokes needed for producing forgings of a prescribed size and shape (compared to a conventional forge), the forging process requires less reheating between strokes, thereby greatly reducing energy consumption.

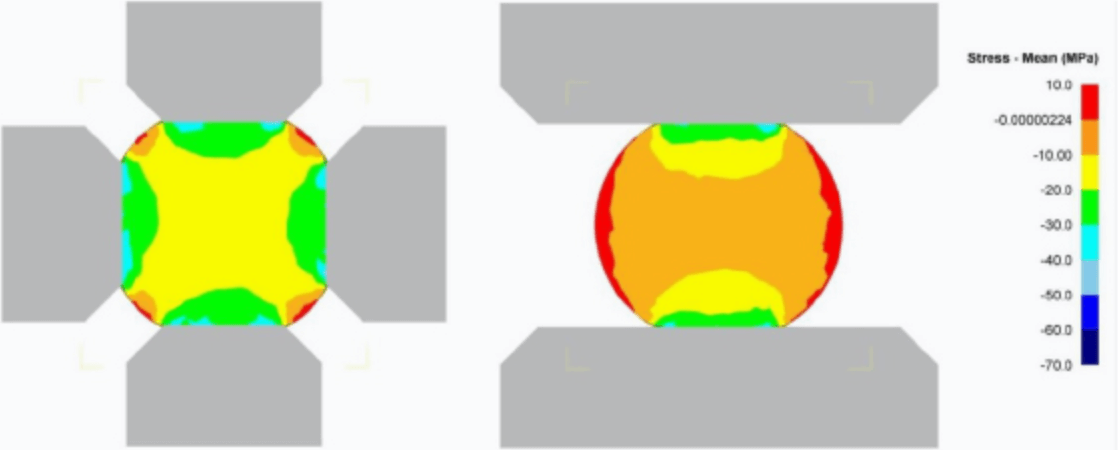

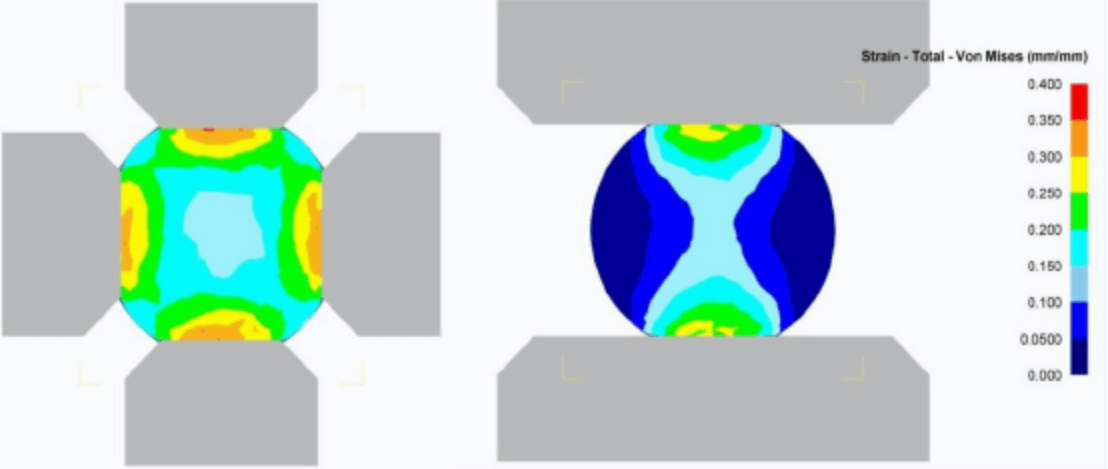

Higher quality steel

Compared to conventional forging methods, with an FDFD the cast metal structure is subjected to a deeper deformation process during the contraction schedule, without any release of stress. This results in the production of physically and mechanically superior forgings.

Stresses in 4-die and 2-die forging fabrication

[Video]

Advanced Material Japan Corporation supports the introduction of FDFDs in accordance with the needs and production facility specifications of its Japanese customers. To help customers evaluate the adoption of an FDFD, we can produce steel materials on contract using an FDFD in Russia or another country.

Advantages of AMJ

-

1

PERFORMANCESpecialist in high-volume procurement and processing

For anything ranging from massive procurements of materials in quantities of 100 tons or more, to advanced refining of materials for parts manufacturing, we can prepare proposals for your specific needs.

-

2

FLEXIBILITYWe accept orders for small and large lots.

We can tailor the quantity and schedule of deliveries to your needs, from one-off procurements of tons of material, to regular, continual deliveries in smaller quantities.

-

3

SAFETYRegular, legitimate procurement for safety and a sense of security

Since all of AMJ’s procurement deals with clients are based on regular and fully legal contracts, clients can use our materials with peace of mind.

-

4

AVAILABILITYIf you need multiple materials simultaneously, leave it to us!

In a great many real-world applications, multiple materials are needed at the same time. AMJ can arrange to provide you with all the materials you need in a single order and procurement.

Flow of transactions

-

STEP 1Inquiries

Firstly, feel free to consult us using the inquiry form.

-

STEP 2Conversation

One of our staff will speak to you about the materials you want to use and how you want to use them.

-

STEP 3Our proposal

Based on the conversation, we provide you with a proposal to meet your needs, including a cost estimate.

-

STEP 4Contract

Once the proposal details and estimate are finalized and agreed, a formal contract is signed.

-

STEP 5Delivery

We deliver the resources and materials you need for an optimal solution, based on our proposal.

For further information ranging from procurement of

materials to practical applications, please contact us.

Facilities

For further information ranging from procurement of

materials to practical applications, please contact us.